Introduction

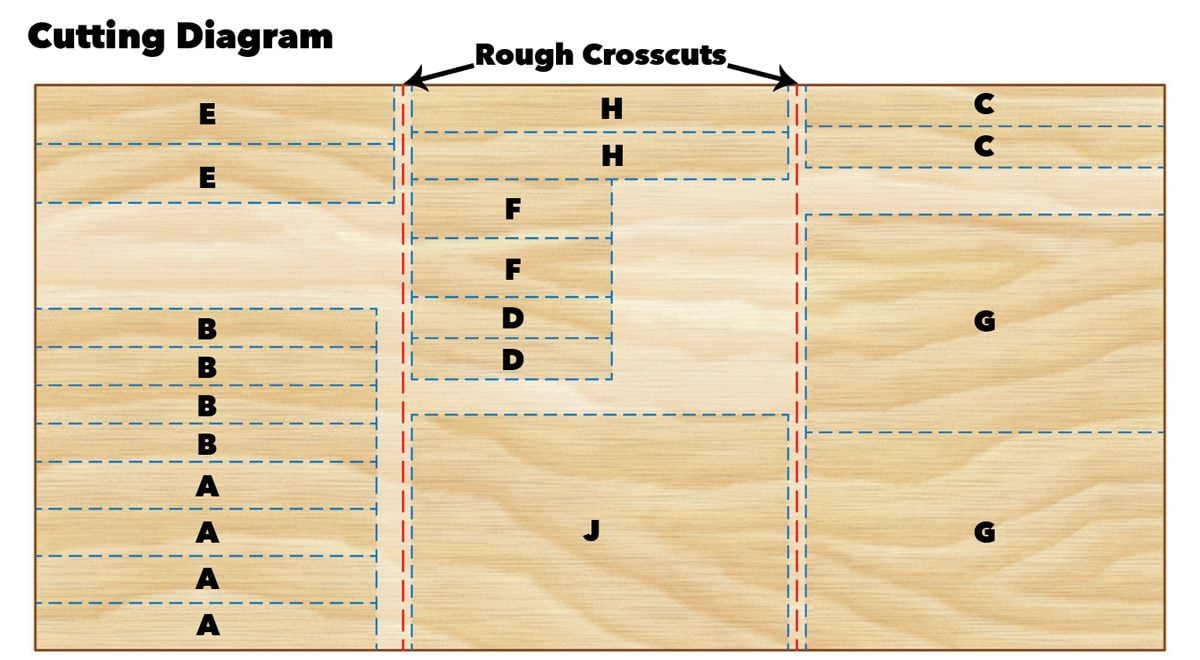

Build a simple rolling shop cart to transport heavy toolboxes and pieces of wood from one end of the shop to the other. All you need is a sheet of 3/4-in. plywood.

Tools Required

- Air compressor

- Air hose

- Brad nail gun

- Circular saw

- Clamps

- Cordless drill

- Countersink drill bit

- Framing square

- Hearing protection

- Miter saw

- Safety glasses

- Straightedge

- Table saw

- Wood glue

Getting Started

Whether your shop is big or small, it's sure handy to have a cart or two for moving stacks of parts from one machine to another. Carts make an endless journey around a shop, from planer to table saw to drill press to the sander, and on and on. They're never empty!

Constructing this cart is simple—all the parts are just glued and screwed or nailed together. You'll need one full sheet of 3/4-in. plywood and a box of 1-1/4-in. screws.

Plus, learn how to tame the clutter and work smarter with these ingenious (and inexpensive!) workshop storage tips you can DIY.

Original article and pictures take http://www.familyhandyman.com/workshop/workbench/rolling-tool-box-cart-plans/view-all site

Комментариев нет:

Отправить комментарий